|

Solar

Pumping: Plumbing Design & Glossary |

Plumbing Design, Pipe Sizing Chart, Pressure

& Flow rate, Pump Glossary

Plumbing and Storage Tank

Solar Pump Peripherals: Water Storage, Control and

Monitoring

Storage tank capacity

Generally, your storage capacity should be equal to 3 to 10 days of average

water consumption, or more. This depends on your climate and your usage

patterns. For domestic use in a cloudy climate, 10 days is minimal. In

a sunny climate, this allows for a generous safety margin. For irrigation

of deeply rooted crops or trees, 3 days' storage may be adequate because

the earth itself provides storage. For irrigating a garden, 5 days may

be adequate. More is always better, unless evaporation loss is excessive.

Storage tank plumbing

(Refer to Storage Tank Plumbing Illustration above)

Place your normal point of discharge higher than the bottom of your

water tank, in order to hold a reserve so that the tank does not run completely

dry. You can lose your water supply under any of these circumstances:

1. a period of low sunshine and/or excessive water demand

2. an electrical or mechanical failure in the system

3. a leak in the tank or piping

4. an accidental discharge of stored water

Place a second outlet valve at the bottom level of your storage tank,

in order to discharge the reserve supply in case of emergency.

Float switch for full-tank shutoff

We recommend the use of a float switch to prevent overflow of your tank.

It will stop the pump when the tank fills, then will reset when the level

drops. This conserves ground water, prevents overflow, and eliminates

unnecessary pump wear. Solar pump controllers allow the use of small-sized

cable to a remote float switch.

Defeating the float switch:

You may want to defeat your float switch

1. to allow overflow for irrigation purposes or

2. to test or observe your system.

To do this, install a switch to disconnect one of the two float switch

wires. Use any size of on/off switch available from an electrical supply

or hardware store.

Refresher valve

A refresher valve is an intentional slow leak. During times of low water

demand, it reduces stagnation and may help prevent freezing. It can be

any small valve, installed just below the float switch reset level. When

it is needed, adjust it for a very slow flow and pipe the flow to a place

where it will drain away.

Monitoring the pump

Will you be able to observe the output of your pump at the point of discharge?

If not, you may not know if it malfunctions, especially in the case of

a submersible pump. Consider installing a water meter, or additional valves

so that the flow can be observed.

Monitoring the water level in your storage tank

If your pump malfunctions, will you be able to observe the level of your

tank dropping? If you cannot easily see into your storage tank, here are

some methods of tank monitoring:

1.dipstick in the air vent

2.float with a visible rod that protrudes through the top of the tank

3.float with a rope and pulley to a hanging indicator

4.clear sight-tube alongside the tank

5.sensitive pressure gauge (note:2.3 feet=1 PSI).

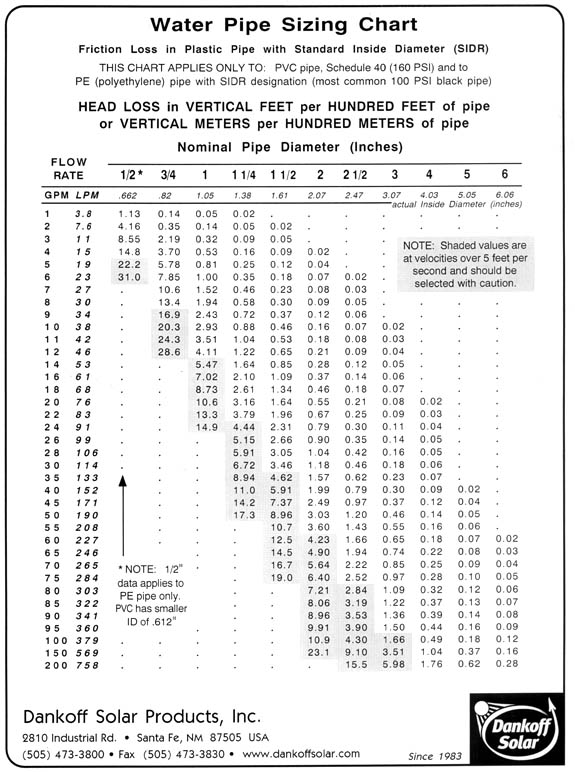

Pipe sizing:

The pipe from the pump to the tank must be carefully sized, depending

on the flow and the length of pipe. A single pipe may be used as both

fill and discharge. In that case, size the pipe for the maximum discharge

that you want to accomplish. Also, consider oversizing the pipe if there

is a chance that you may want to install a larger pump in the future.

Sizing the pipe larger than necessary will NOT influence the performance

of the system..

If you will be using gravity flow to supply water from the storage tank

at a relatively low pressure, then be sure that the discharge pipe is

large enough to allow sufficient flow to meet the maximum water demand,

with very little friction loss. Every 2.3 feet of verticle drop produces

1 PSI pressure

Copyright ©2002 by Dankoff Solar Products, Inc.

Comparing Pressure & Flow

Rates of Different Pumps

Pressure: the force that water pushes out measured in Pounds per

SQ. Inch (PSI) or in feet of head.

|

PSI

|

Head (in Ft.)

|

Pump uses

|

|

0 to 15

|

0 to 35

|

heat circulators, water transfer (i.e. bilge pump),

flood type irrigation, shallow well depth

|

|

15 to 60

|

35 to 140

|

regular house pressure, drip or spray irrigation,

medium well depth

|

|

125

|

290

|

fire protection, deeper wells, working limit for

regular plumbing

|

|

240

|

550

|

deep wells, limit for DC submersible pumps

|

|

520

|

1200

|

high pressure washers, very deep well, limit for

Solamotor Jack pump

|

Flow rate: how much water is moved over time. Usually per minute.

|

Flow Rate

Gal./ minute

|

Pumps & Uses

|

|

0 to 1

|

windmills, deep well DC pumps, small heat circulators

|

|

2 to 5

|

1 or 2 house faucets, small pressure pump, shallow

well DC pump

|

|

5 to 10

|

typical flow for house with garden,deep well AC

pump

|

|

10 to 20

|

medium irrigation or fire protection

|

|

over 20

|

commercial irrigation or fire protection

|

Copyright ©2005 by SolarRay, Inc.

Glossary of Solar Water Pumping

Terms

Pumps & Related Components

by Windy Dankoff

Booster Pump - A surface pump used to increase pressure in a water line,

or to pull from a storage tank and pressurize a water system. See surface

pump.

Centrifugal Pump - A pumping mechanism that spins water by means of an

"impeller". Water is pushed out by centrifugal force. See also

multi-stage.

Check Valve - A valve that allows water to flow one way but not the other.

Diaphragm Pump - A type of pump in which water is drawn in and forced

out of one or more chambers, by a flexible diaphragm. Check valves let

water into and out of each chamber.

Foot Valve - A check valve placed in the water source below a surface

pump. It prevents water from flowing back down the pipe and "losing

prime". See check valve and priming.

Positive Displacement Pump - Any mechanism that seals water in a chamber,

then forces it out by reducing the volume of the chamber. Examples: piston

(including jack), diaphragm, rotary vane. Used for low volume and high

lift. Contrast with centrifugal. Synonyms: volumetric pump, force pump.

Impeller - See centrifugal pump

Jet Pump - A surface-mounted centrifugal pump that uses an "ejector"

(venturi) device to augment its suction capacity. In a "deep well

jet pump", the ejector is down in the well, to assist the pump in

overcoming the limitations of suction. (Some water is diverted back down

the well, causing an increase in energy use.)

Multi-Stage Centrifugal - A centrifugal pump with more than one impeller

and chamber, stacked in a sequence to produce higher pressure. Conventional

AC deep well submersible pumps and higher power solar submersibles work

this way.

Priming - The process of hand-filling the suction pipe and intake of

a surface pump. Priming is generally necessary when a pump must be located

above the water source. A self-priming pump is able to draw some air suction

in order to prime itself, at least in theory. See foot valve.

Pulsation Damper - A device that absorbs and releases pulsations in flow

produced by a piston or diaphragm pump. Consists of a chamber with air

trapped within it.

Pump Jack - A deep well piston pump. The piston and cylinder is submerged

in the well water and actuated by a rod inside the drop pipe, powered

by a motor at the surface. This is an old-fashioned system that is still

used for extremely deep wells, including solar pumps as deep as 1000 feet.

Sealed Piston Pump - See positive displacement pump. This is a type of

pump recently developed for solar submersibles. The pistons have a very

short stroke, allowing the use of flexible gaskets to seal water out of

an oil-filled mechanism.

Self-Priming Pump - See priming.

Submersible Pump - A motor/pump combination designed to be placed entirely

below the water surface.

Surface Pump - A pump that is not submersible. It must be placed no more

than about 20 ft. above the surface of the water in the well. See priming.

(Exception: see jet pump)

Vane Pump - (Rotary Vane) A positive displacement mechanism used in low

volume high lift surface pumps and booster pumps. Durable and efficient,

but requires cleanly filtered water due to its mechanical precision.

Solar Pump Components

DC Motor, Brush-Type - The traditional DC motor, in which small carbon

blocks called "brushes" conduct current into the spinning portion

of the motor. They are used in DC surface pumps and also in some DC submersible

pumps. Brushes naturally wear down after years of use, and may be easily

replaced.

DC Motor, Brushless - High-technology motor used in centrifugal-type

DC submersibles. The motor is filled with oil, to keep water out. An electronic

system is used to precisely alternate the current, causing the motor to

spin.

DC Motor, Permanent Magnet - All DC solar pumps use this type of motor

in some form. Being a variable speed motor by nature, reduced voltage

(in low sun) produces proportionally reduced speed, and causes no harm

to the motor. Contrast: induction motor

Induction Motor (AC) - The type of electric motor used in conventional

AC water pumps. It requires a high surge of current to start and a stable

voltage supply, making it relatively expensive to run from by solar power.

See Inverter.

Linear Current Booster (LCB)- An electronic device which varies the voltage

and current of a PV array to match the needs of an array-direct pump,

especially a positive displacement pump. It allows the pump to start and

to run under low sun conditions without stalling. Electrical analogy:

variable transformer. Mechanical analogy: automatic transmission. Also

called pump controller. See pump controller .

Pump Controller An electronic device that controls or process power to

an array-direct pump. It may perform any of the following functions: stopping

and starting the pump; protection from overload; power convertion or power

matching (see linear current booster).

Water Well Components

Borehole - Synonym for drilled well, especially outside of North America.

Casing - Plastic or steel tube that is permanently inserted in the well

after drilling. Its size is specified according to its inside diameter.

Cable Splice - A joint in electrical cable. A submersible splice is made

using special materials available in kit form.

Drop Pipe - The pipe that carries water from a pump in a well up to the

surface.

Perforations - Slits cut into the well casing to allow groundwater to

enter. May be located at more than one level, to coincide with water-bearing

strata in the earth.

Pitless Adapter - A special pipe fitting that fits on a well casing,

below ground. It allows the pipe to pass horizontally through the casing

so that no pipe is exposed above ground where it could freeze. The pump

may be installed and removed without further need to dig around the casing.

This is done by using a 1 inch threaded pipe as a handle.

Safety Rope - Plastic rope used to secure the pump in case of pipe breakage.

Submersible Cable - Electrical cable designed for in-well submersion.

Conductor sizing is specified in millimeters, or (in USA) by American

Wire Gauge (AWG) in which a higher number indicates smaller wire. It is

connected to a pump by a cable splice.

Well Seal - Top plate of well casing that provides a sanitary seal and

support for the drop pipe and pump. Alternative: See pitless adapter

Water Well Characteristics

Driller's Log - The written form on which well characteristics are recorded

by the well driller. In most states, drillers are required to register

all water wells and to send a copy of the log to a state office. This

supplies hydrological data and well performance test results to the public

and to the well owner.

Drawdown - Lowering of level of water in a well due to pumping.

Recovery Rate - Rate at which groundwater refills the casing after the

level is drawn down. This is the term used to specify the production rate

of the well.

Static Water Level - Depth to the water surface in a well under static

conditions (not being pumped). May be subject to seasonal changes or lowering

due to depletion.

Wellhead - Top of the well, at ground level.

Pump System Engineering

Friction Loss - The loss of pressure due to flow of water in pipe. This

is determined by 3 factors: pipe size (inside diameter), flow rate, and

length of pipe. It is determined by consulting a friction loss chart available

in an engineering reference book or from a pipe supplier. It is expressed

in PSI or Feet (equivalent additional feet of pumping).

Head - See synonym: vertical lift.

Suction Lift - Applied to surface pumps: Vertical distance from the surface

of the water in the source, to a pump located above surface pump located

above. This distance is limited by physics to around 20 feet at sea level

(subtract 1 ft. per 1000 ft. altitude) and should be minimized for best

results.

Submergence - Applied to submersible pumps: Distance beneath the static

water level, at which a pump is set. Synonym: immersion level.

Total Dynamic Head - vertical lift + friction loss in piping (see friction

loss).

Vertical Lift - The vertical distance that water is pumped. This determines

the pressure that the pump pushes against. Total vertical lift = vertical

lift from surface of water source up to the discharge in the tank + (in

a pressure system) discharge pressure. Synonym: static head. Note: Horizontal

distance does NOT add to the vertical lift, except in terms of pipe friction

loss. NOR does the volume (weight) of water contained in pipe or tank.

Submergence of the pump does NOT add to the vertical lift in the case

of a centrifugal type pump. In the case of a positive displacement pump,

it may add to the lift somewhat.

Water Distribution

Cut-In Pressure and Cut-Out Pressure - See pressure switch.

Gravity Flow - The use of gravity to produce pressure and water flow.

A storage tank is elevated above the point of use, so that water will

flow with no further pumping required. A booster pump may be used to increase

pressure. 2.31 Vertical Feet = 1 PSI. See pressure.

Head - See vertical lift and total dynamic head. In water distribution,

synonym: vertical drop.

Open Discharge - The filling of a water vessel that is not sealed to

hold pressure. Examples: storage (holding) tank, pond, flood irrigation.

Contrast: pressure tank.

Pressure - The amount of force applied by water that is either forced

by a pump, or by the gravity. Measured in pounds per square inch (PSI).

PSI = vertical lift (or drop) in Feet / 2.31.

Pressure Switch - An electrical switch actuated by the pressure in a

pressure tank. When the pressure drops to a low set-point (cut-in) it

turns a pump on. At a high point (cut-out) it turns the pump off.

Pressure Tank - A fully enclosed tank with an air space inside. As water

is forced in, the air compresses. The stored water may be released after

the pump has stopped. Most pressure tanks contain a rubber bladder to

capture the air. If so, synonym: captive air tank.

Pressure Tank Precharge - The pressure of compressed air stored in a

captive air pressure tank. A reading should be taken with an air pressure

gauge (tire gauge) with water pressure at zero. The air pressure is then

adjusted to about 3 PSI lower than the cut-in pressure (see Pressure Switch).

If precharge is not set properly, the tank will not work to full capacity,

and the pump will cycle on and off more frequently.

Copyright ©2002 by Dankoff Solar Products, Inc.

|